Lead Smelting

Lead Pollution

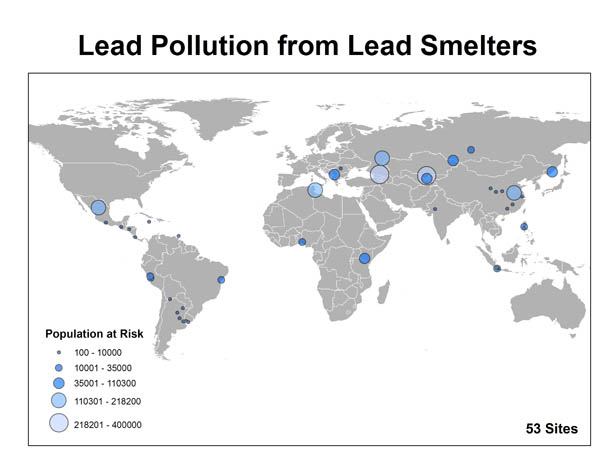

Estimated Population at Risk:

1.9 Million

Description

Lead processing and smelting plants work with both primary and secondary lead. Primary lead is mined, separated from ore, and refined into various products, whereas secondary lead is recovered from used objects – such as used lead-acid batteries – for reuse in other products. Smelting is a key process in lead product production, and involves heating lead ore or recovered lead with chemical reducing agents. Both secondary and primary smelting processes can be responsible for releasing large amounts of lead contamination into the surrounding environment.

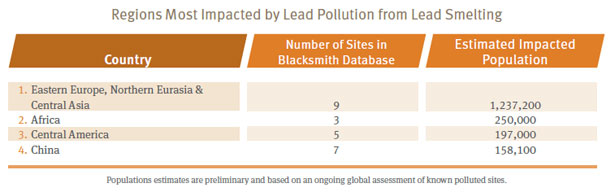

Populations estimates are preliminary and based on an ongoing global assessment of known polluted sites.

Industrial Process

Lead processing either requires the mining of new, primary lead, or the recycling of used products and scrap metals. Both forms of lead must be melted using a smelting process in order to obtain pure and usable forms of the metal.

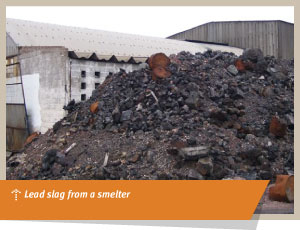

The primary smelting process involves separating lead from ore using heat and reducing or purifying agents such as coke and charcoal. Once the lead ore is mined, it must undergo several different processes in order to be turned into usable or metallurgical lead material: sintering, smelting, and refining. The sintering phase involves removing sulfur from the lead ore using a hot air combustion process. Once the sulfur is removed, the lead is sent into a smelter where it is heated at extremely high temperatures in order to isolate the pure lead from other metals and materials in the ore. Any remaining metals or other materials left after the smelting are removed during the refining process.29 Lead dust and smoke can be released during all of the above processes, and slag contaminated with lead particles may be left over after the smelting process.

The primary smelting process involves separating lead from ore using heat and reducing or purifying agents such as coke and charcoal. Once the lead ore is mined, it must undergo several different processes in order to be turned into usable or metallurgical lead material: sintering, smelting, and refining. The sintering phase involves removing sulfur from the lead ore using a hot air combustion process. Once the sulfur is removed, the lead is sent into a smelter where it is heated at extremely high temperatures in order to isolate the pure lead from other metals and materials in the ore. Any remaining metals or other materials left after the smelting are removed during the refining process.29 Lead dust and smoke can be released during all of the above processes, and slag contaminated with lead particles may be left over after the smelting process.

Secondary smelting of lead is similar to primary smelting, but does not require the initial sintering process. Once lead is recovered from used materials – with the majority coming form used lead-acid batteries – it is placed into a furnace where it is heated with coke or charcoal in order to isolate the lead from other compounds. Like primary lead smelting, the processing of secondary lead can also produce lead dust and toxic slag. If smelting plants and equipment are not properly constructed to minimize the release of pollutants, lead toxins can often enter the surrounding environment and contaminate soil, water, and food.

In addition, the mining process for extracting primary lead ore – if not performed with the necessary safety and environmental precautions – can create large piles of waste that contains lead toxins. If these piles are left out in the open, lead dust can be blown into surrounding areas, and lead can also leach into the ground and contaminate water systems.

Global Context

Lead is a very useful material found in many different products, with approximately six million tons used annually across the world.30 Though much of this lead is recycled and reused, the US Geological Survey estimated that the world production of primary lead in 2009 was over 3.8 million metric tons.31 The extraction and smelting of lead can cause a large amount of toxic pollution, and emissions from lead smelting are a big contributor to global lead contamination.32 Lead smelting can also pollute the environment with large amounts of particulate matter, toxic effluents, and other various solid wastes.

Though lead smelting facilities exist all over the world, countries and cities where pollution may not be properly monitored by environmental and health regulations are more negatively impacted by health problems related to lead contamination. According to the Blacksmith inventory, countries in Eastern Europe, Northern Eurasia, and Central Asia are particularly at risk from lead smelting activities, with an estimated two million people impacted worldwide.

Exposure Pathways

The most common route of lead exposure caused by lead smelting is through inhalation or ingestion of lead dust, particles, or exhaust from the burning process. Workers in the smelting factories are particularly at risk, as they can be exposed to prolonged and direct inhalation of gaseous emissions and dust. Particles and ash containing lead can also be blown into nearby towns or onto agricultural fields, which can contaminate livestock and crops. Studies in China have found that certain crops, such as corn, are particularly susceptible to lead accumulation when grown in close proximity to smelters.34 Dermal contact with soil contaminated with lead can also expose people to toxins.

In addition to toxic emissions, lead smelting produces wastewater, solid waste, and slag heaps that may be contaminated with heavy metal. Lead from these sources, as well as waste rock from lead ore mining, can often make its way into ground and surface water systems that are used for drinking, bathing, and cooking.

Health Effects

The health effects of exposure to lead can be both acute and chronic, and the problems caused by lead poisoning are particularly dangerous and severe for children. Acute lead poisoning can happen immediately and is often caused by inhaling large quantities of lead dust or fumes in the air. Chronic lead poisoning, however, occurs over longer periods of time and can result from very low-level, but constant, exposure to lead. Chronic poisoning is far more common than acute exposure and can be caused by persistent inhaling or ingestion of lead, or, over much longer periods, can result in lead accumulation in the bones.

Health problems associated with lead poisoning can include reduced IQ, anemia, neurological damage, physical growth impairments, nerve disorders, pain and aching in muscles and bones, memory loss, kidney disorders, retardation, tiredness and headaches, and lead colic, which impacts the abdomen.19 Severe exposure to high concentrations of lead can lead to dire health risks, including seizures, delirium, coma, and in some cases, death.

Neurological damage is especially pronounced in children suffering from lead exposure, with even small amounts of lead poisoning capable of causing lifelong developmental and cognitive problems. Exposure to lead in utero can also cause birth defects.

What is Being Done

Many modern and well-maintained lead smelting facilities have infrastructure in place that allow pollution levels to be controlled and monitored according to environmental and health standards. However, these kinds of operations can be quite expensive, which leads many smelting plants to forego important safety measures. This is particularly common in countries or areas where there is little to no government regulation of the industry. Thus, one of the most effective ways to reduce lead pollution from smelters is to work with governments, NGOs, and communities to update equipment and operations at the plants.

Several of the older lead smelters, some of which have been in operation for many decades, have created large areas of legacy pollution. Remediation efforts in these areas have to consist of both the removal and disposal of contaminated soil or material and to ensure that contaminated water and food are able to return to safe consumption levels.

Example – DALY Calculations

A city in northwestern India is home to a large smelter that is releasing lead toxins into the nearby environment. There are many lakes in this region, and lead has contaminated the drinking and bathing water for the nearby residents. Samples of water near the smelter found 430 parts per billion of lead, which is over 8 times the health standard. Blacksmith estimates that 3,000 people at this site are at risk of diseases caused by lead exposure.

DALYs associated with adverse health impacts from lead exposure at this site are estimated to be 47,917 for the estimated exposed population of 3,000. This means that the 3,000 affected people will have a collective 47,917 years lost to death, or impacted by disease or disability. This comes out to 16 years lost or lived with a disability per person.

Footnotes

[19]: “New Basel guidelines to improve recycling of old batteries.” United Nations Environment Programme. May 22, 2002.

Available at: http://www.unep.org/Documents.Multilingual/Default.asp?DocumentID=248&ArticleID=3069&I=en.

[29]: “Primary Metals: Lead Processing.” Illinois Sustainable Technology Center, Prairie Research Institute. Accessed on August 31, 2011.

Available at: http://www.istc.illinois.edu/info/library_docs/manuals/primmetals/chapter6.htm.

[30]: Roberts, H. “Changing Patterns in Global Lead Supply and Demand.” Journal of Power Sources, Vol. 116, No. 1-2 (2003): 23-31.

[31]: Kelly, Thomas D., et al. “Historical Statistics for Mineral and Material Commodities in the United States: Lead.” U.S. Geological Survey Data Series 140, Version 2010. Available at: http://minerals.usgs.gov/ds/2005/140/#lead.

[32]: Dudka, S. and D.C. Adriano. “Environmental Impacts of Metal ore Mining and Processing: A review.” Journal of Environmental Quality, Vol. 26, No. 3 (1997): 590-602.

[33]:“Environmental, Health, and Safety Guidelines: Base Metal Smelting and Refining.” International Finance Corporation. World Bank Group. April 30, 2007.

Available at: http://www.ifc.org/ifcext/enviro.nsf/AttachmentsByTitle/gui_EHSGuidelines2007_SmeltingandRefining/$FILE/Final+-+Smelting+and+Refining.pdf.

[34]: Xiangyang, Bi, et al. “Allocation and Source Attribution of Lead and Cadmium in Maize (Zea mays L.) impacted by smelting emissions.” Environmental Pollution, Vol. 157, No. 3 (2009): 834-839.

-

Artisanal Gold Mining

Mercury Pollution

-

Industrial Estates

Lead Pollution

-

Agricultural Production

Pesticide Pollution

-

Lead Smelting

Lead Pollution

-

Tannery Operations

Chromium Pollution

-

Mining and Ore Processing

Mercury Pollution

-

Mining and Ore Processing

Lead Pollution

-

Lead-Acid Battery Recycling

Lead Pollution

-

Arsenic in Groundwater

Arsenic Pollution

-

Pesticide Manufacturing and Storage

Pesticide Pollution

-

The Rest of the Toxic Twenty